If you are looking for ways to optimise the energy efficiency of your home in order to cut back and save on heating costs, then you should definitely look into installing a Heat Recovery and Ventilation System. Not only does this system allow you to save costs, but it also reduces greenhouse gas emissions from Heating Ventilation and Air Conditioning (HVAC) which contribute to contribute towards climate change and global warming in a significant way.

Equipping your household with a Heat Recovery Ventilation (HRV), also known as Mechanical Ventilation Heat Recovery (MVHR), system can increase the efficiency of HVAC systems by recovering up to 95% of the heat energy present in exhaust gases. This saves energy, drives down costs and leads to fewer greenhouse emissions, resulting in a more sustainable environment; however, before an HRV system can be installed, you need to make sure that the building is airtight and well insulated.

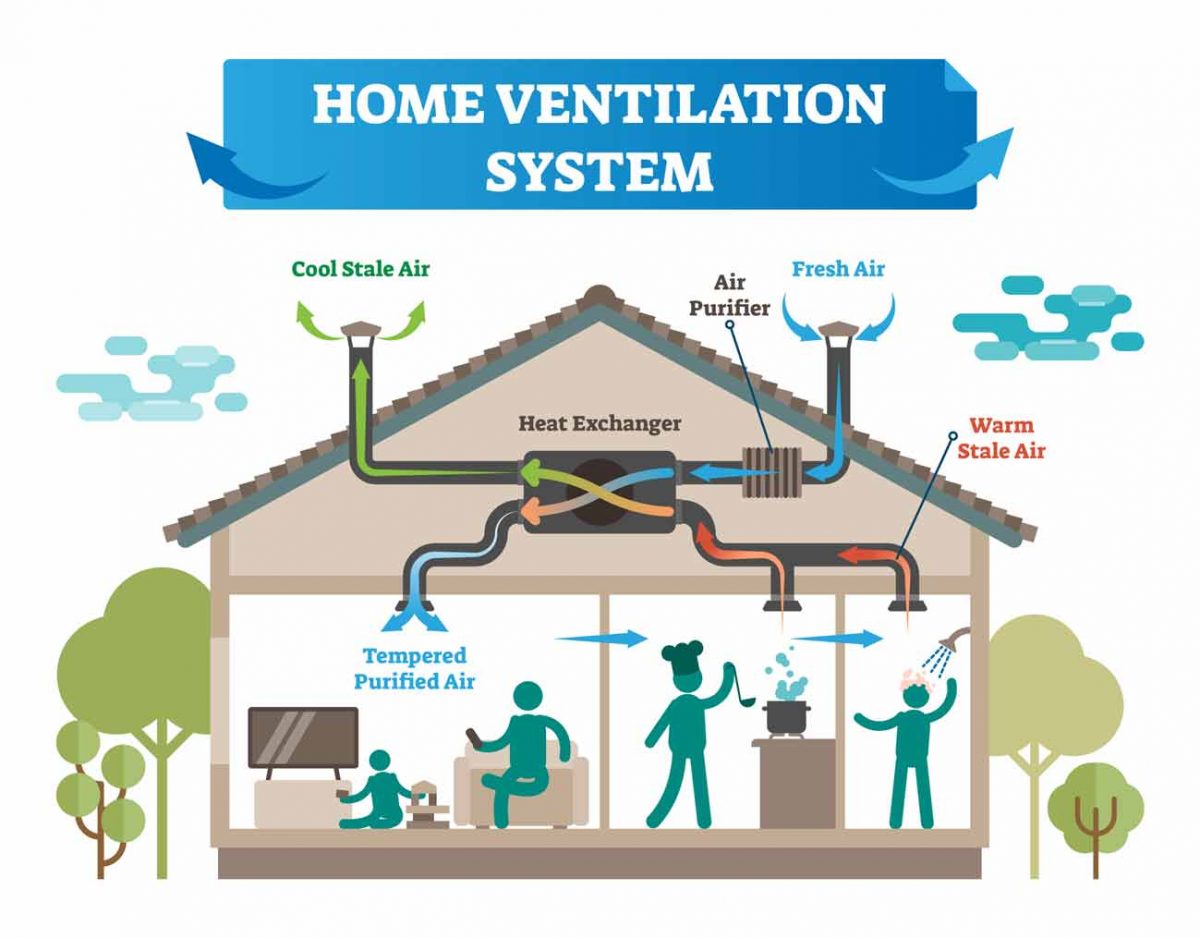

What is a Heat Recovery Ventilation (HRV) System and how does it work?

HRV systems consist of two ventilation ducts/pipes running next to one another, passing between the inside and the outside of a house. One carries cool, fresh air in; the other carries moist, stale air out. Both airstreams pass through a central Heat Exchanger Unit without coming into contact with one another. The Heat Exchanger transfers the waste heat energy from the outgoing stream to the in-going stream. This recycling of energy means that the building can remain ventilated with fresh air, without losing much of its heat energy. Conversely, during summer seasons, the heat exchanger can also cool down the incoming hot air by transferring its energy to the outgoing cold air. HRV systems typically come with blower fans in the inlet and outlet streams to control the airflow as required, either manually or automatically. The system is usually installed on the roof or the building façade.

One special type of an HRV system is known as an Energy Recovery Ventilation (ERV) system. It has all the features of a typical HRV system, with the added bonus of exchanging humidity between the inlet and outlet airstreams. This is achieved by the use of a membrane in the center of the heat exchanger which traps moisture and allows it to flow from a higher concentration to a lower concentration. In humid climates, this helps keep the excess moisture outside the building while keeping it ventilated with fresh air.

There are two prerequisite that must be met, however, before one can take advantage of an HRV system. Firstly, the airtightness of the building must be below 3 air changes per hour when tested at 50 Pascal. What this means is that if the building is not sufficiently airtight, HRV systems will not provide much benefit. This is because draughts could bypass the HRV system completely and work against it, cooling the air inside too much and the expense wouldn’t be worth it. The second prerequisite is that the building must be well insulated, thermally. If heat is lost readily, then the HRV system cannot maintain a desirable internal environment.

Types of Heat Recovery Ventilation (HRV) systems

Depending upon the construction of the Heat Exchanger Unit, HRV systems can be classified into various types; Rotary thermal wheels, Fixed plate heat exchangers, Heat pipes, Run-around systems and Phase Change Materials systems.

Rotary Thermal Wheels

A rotary thermal wheel system uses a rotating porous metallic wheel which passes through both inlet and outlet airstreams. The wheel absorbs energy and moisture from the hotter, more humid airstream and transfers it to the cooler, drier airstream. In addition, some rotary wheels also employ silica-based gels, which can be used to exchange moisture between the two air-streams.

Fixed Plate Heat Exchangers

These are the most commonly found heat exchangers in buildings. These consist of thin metal plates, stacked such that there is very small spacing between the individual plates. Both inlet and outlet airstreams pass through these plates without coming into contact with one another. The heat transfer occurs from the hotter airstream, through the metal plates, and into the cooler airstream. These systems can reach up to 90% efficiency mainly due to the design of the metal plates and the materials used.

Heat Pipes

In Heat Pipes, the energy transfer takes place using an evaporator and a condenser housed in a sealed pipe containing a special fluid. The fluid absorbs or releases thermal energy by changing states i.e. from liquid to gas (evaporation) and from gas back to liquid (condensation). The liquid absorbs energy from the hot airstream in the evaporator and becomes a gas. The gas is then channeled into a condenser where it releases its energy to the cold airstream and becomes a liquid again. The liquid is then transferred back to the condenser using pressure or gravity, to start the cycle again.

Run-around Systems

The Run-around system combines the features of both the Fixed Plate Heat Exchangers and Heat Pipes to form a hybrid that is more efficient than the individual systems. Typically, both hot and cold airstreams are kept physically separate and attached to two different Fixed Plates. The Fixed Plates themselves are placed in an insulated closed loop containing a fluid which transfers the energy between both fixed plates as it heats and cools. A pump is usually used to keep the liquid flowing in the loop.

Phase Change Materials

Phase Change Materials (PCMs) work in a different manner as compared to the aforementioned HRV systems. PCMs are replacements for traditional building materials and have up to 12 times more thermal storage capacity. The building itself, then, can absorb the excess heat energy inside and release it later when it is needed. This can help to maintain the temperature inside a building, although research into this technology is still ongoing.

Advantages of HRV systems

Helps maintain a healthier indoor environment

The HRV system provides a constant flow of fresh air into a building. At the same time, it extracts humid, polluted air from sources such as the kitchen, bathroom, toilets and utility rooms. The air is also typically filtered through HRV system, removing dust and fungal spores from the airstreams. This keeps the indoor air clean, prevents the formation of mold, and keeps humidity at a comfortable level. It also prevents unpleasant odors in rooms, and saves appliances from dust build-up.

Lower Carbon Footprint

By making efficient use of the thermal energy present in exhaust airstreams, HRV systems help reduce the load on central heating and air conditioning systems. Since less energy is wasted, fewer fossil fuels are burned to provide thermal energy for central heating. This helps reduce the amount of greenhouse gases in the environment and dampens the impact of global warming.

Reduced Energy Costs

The running cost of an HRV system is much less compared to the energy savings that it introduces to a building. Since the indoor environment is maintained, with negligible thermal energy wastage, central heating and air conditioning units do not need to run as often. This saves on electricity and fuel bills.

Disadvantages of HRV systems

Installation Costs

HRV systems are not cheap, although newer manufacturing techniques have led to a reduction in prices. Nevertheless, typical costs range from £2000 to above £ 7000 depending upon the quality of the product and its target building type. Besides the unit itself, the ductwork needs to be integrated into the building’s ventilation system which poses additional costs.

Not suitable for all buildings

As mentioned previously, if the building is not sufficiently airtight, there must be additional renovations made to the building before it can reap the benefits of an HRV system. These renovations may be costly depending upon the age of the building and its construction. In some cases, this cost would outweigh the benefits provided by an HRV system. For these buildings, alternate means of ventilation should be considered.

Does not provide cooling or heating by itself

A common misconception is that HRV systems can condition the air within a building and act as dehumidifiers as well. This is not the case. The HRV helps maintain the internal environment of the building; it tries to keep the heat in, rather than generate that heat. Thus, the HRV system should be considered an addition to the heating or cooling solution present in the structure.

Conclusion: Do I need one?

If the building under question has sufficient airtightness and thermal insulation, then the HRV system is practically a necessity. The system provides all the features of a robust ventilation system, while cutting down on energy losses and reducing costs. It prevents mold, filters out unclean air and prevents odors. In many countries, the HRV system may be required to meet building standards and other Air Quality criteria. On the other hand, if the building doesn’t have meet the aforementioned prerequisites, then steps may be taken to meet them first, before installing an HRV system. If these conditions cannot be met, other ventilation solutions should be considered.

Can you paint over wallpaper?

What is the correct preparation needed for painting over wallpaper? If you have wall paper in the room that you would like to paint, and if you're wondering if you can paint over wallpaper [...]

What is the best way to prepare walls before painting?

We like to do the following to best prepare walls before painting: CLEAN WALLS: We recommend to clean the walls first and make sure they are fully dried. REPAIR: We would the recommend to [...]

How much paint do I need to cover my walls and ceiling?

How much paint do I need, and how do I calculate it? If you are trying to estimate the amount of paint you need, you’ve come to the right [...]

Do I have to order a colour chart or tester pot? Why?

YES. It’s always best to order a colour chart and/or tester pot first. WHY? You never want to rely on just the online colour charts, as they are not accurate, monitor colours vary and [...]

Tooba is a UK based scientist, entrepreneur and writer, and we’re pleased to have her on our team! Dedicated to the environment though her writing, she helps creates awareness to reduce environmental impact of our day-to-day operations such as recycling of wastage, focusing on usage of cardboard packaging and compliance with the Energy Saving Opportunity Schemes.